Pump Skids, Pump Skid Systems, and Industrial Pump Skid Packages

Understanding Pump Skids

Pump skids are pre-assembled units that house various types of pumps, including centrifugal pumps, plunger pumps, and booster pumps. These systems facilitate efficient pumping, commonly utilised in industries such as water treatment and chemical processing. By consolidating components into a single framework, pump skids enhance space efficiency and reduce the complexities of installation. The tailored design of each skid accommodates specific pumping requirements, whether for transporting fluids or for applications demanding high pressure, such as in force pump systems. Their versatility in deployment makes pump skids an essential asset for optimising various pumping processes across multiple sectors.

- Efficient space utilisation by combining components into a single unit

- Reduced installation complexity, saving time and resources

- Custom designs to meet specific pumping needs

- Suitable for a wide range of applications, including high-pressure tasks

- Enhanced reliability and maintenance ease due to integrated design

- Facilitates quick deployment in various industrial sectors

- Improves overall system performance and longevity of pumping equipment

What are Pump Skids?

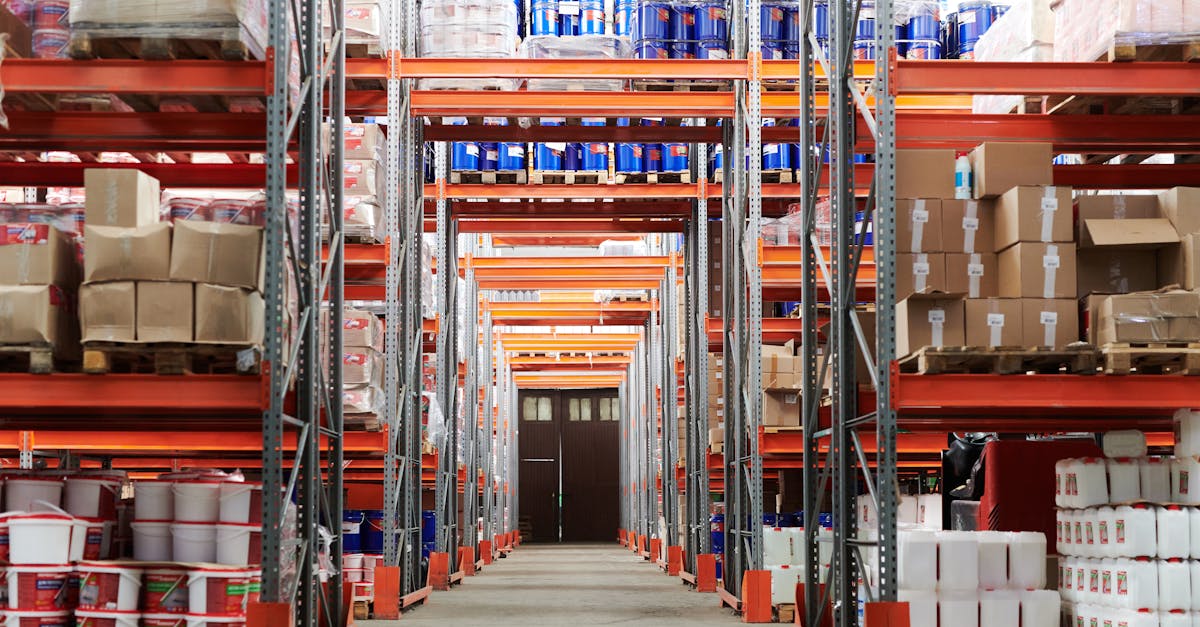

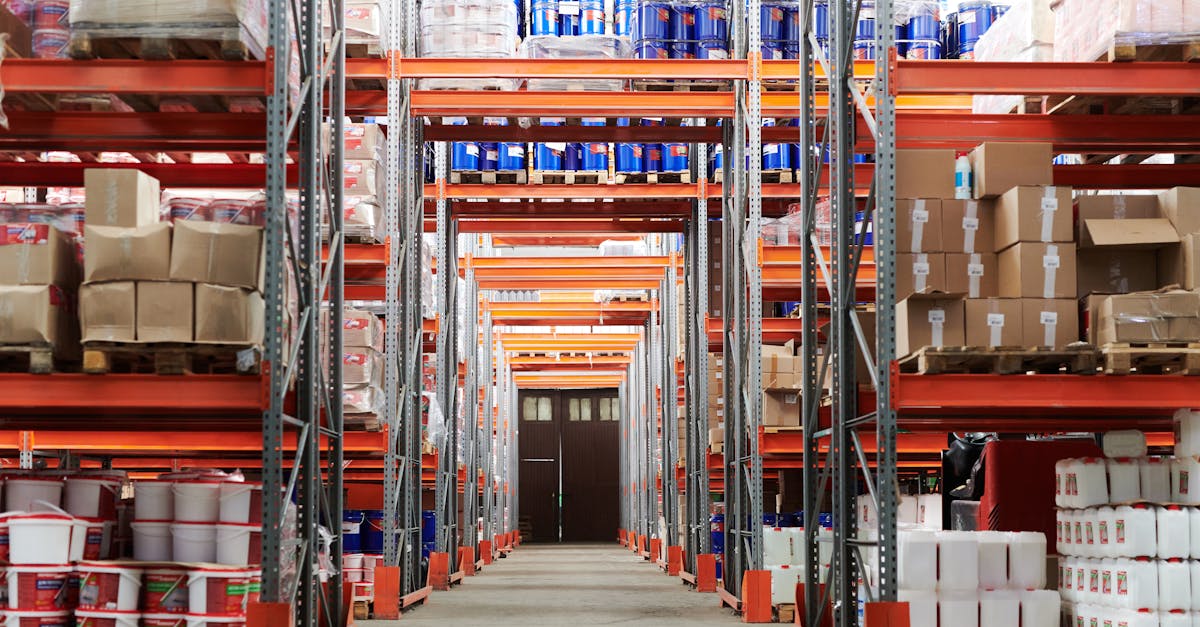

Pump skids are pre-assembled, ready-to-install systems designed to streamline the incorporation of various components, such as metering pumps and injection pumps. These systems typically consist of pipes, hydraulic connections, and sometimes additional features such as monitoring instruments. The compact design of pump skids allows for efficient use of space in pump stations and ensures ease of installation at various locations, including industrial settings and remote sites.

These sled-like structures are engineered to support a range of applications, effectively managing the flow of fluids through pipelines. Pump skids can accommodate different types of pumps, including injection pumps, making them versatile for diverse industries. Their modular nature allows for easier transport and installation, providing a practical solution for transporting and deploying pump stations in challenging environments.

Importance of Choosing the Correct Pump Skid

Selecting the appropriate pump skids is crucial for ensuring optimal performance within various pipeline systems. The right configuration of inline pumps, hydraulic drives, and diaphragm pumps can significantly impact the efficiency of fluid transfer. Proper integration of flow meters and pipe fittings within the skid design allows for precise monitoring and control of fluid dynamics. A well-designed pump skid acts as a robust sled that supports the entire pumping unit, ensuring reliability and safety in the operation of the pipeline system.

Choosing the correct pump skid also influences the overall maintenance and operational costs. Skids that are optimally designed for specific applications can enhance efficiency and reduce energy consumption, ultimately leading to lower operational expenses. The compatibility of the pump skid with existing pipeline systems is vital to avoid complications such as leaks or pressure losses. Investing in the right components ensures long-term reliability and performance, safeguarding against potential downtime in various industrial applications.

Types of Pump Skids

Pump skids serve a variety of functions across different industries, tailored to specific applications. For instance, waterjet pump skids integrate high-pressure pumps with advanced plumbing systems, delivering precision cutting capabilities. Hydrocracking pump skids are essential in refineries, where they facilitate the conversion of heavy oils into lighter products, employing robust inlet valves and plunger mechanisms. In the construction sector, drill pump skids support efficient dewatering operations, often featuring water-cooled systems to manage heat generated during prolonged use. Understanding the various configurations of pump skids, such as those designed for intricate pipework or large-scale industrial applications, is crucial for optimal performance and longevity.

Overview of Pump Skid Systems

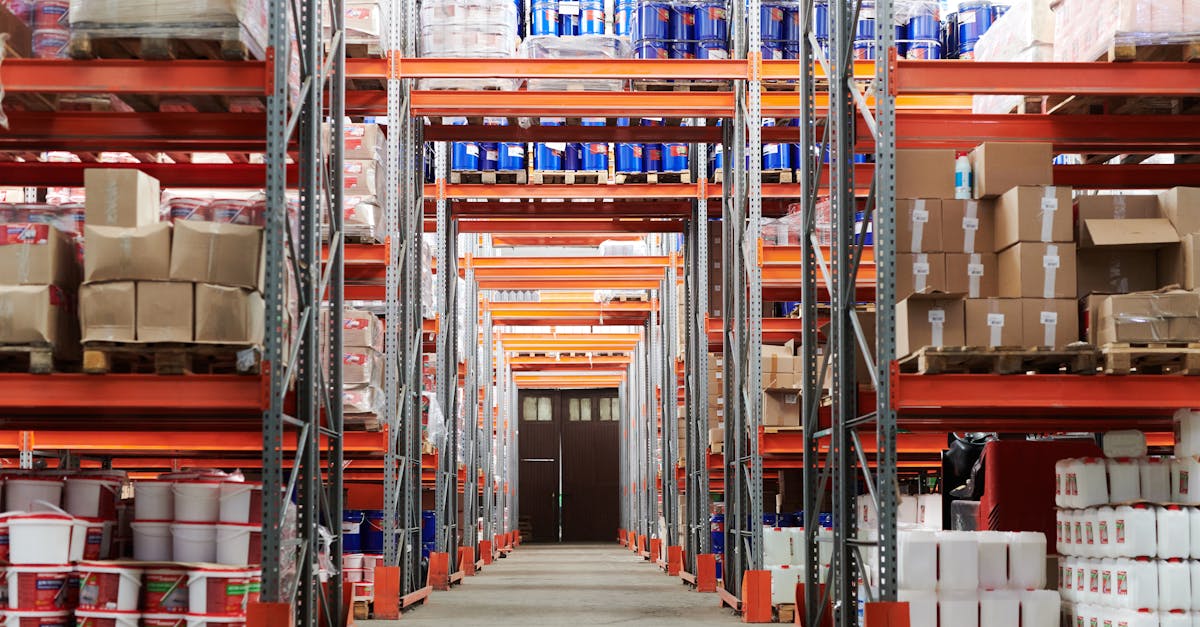

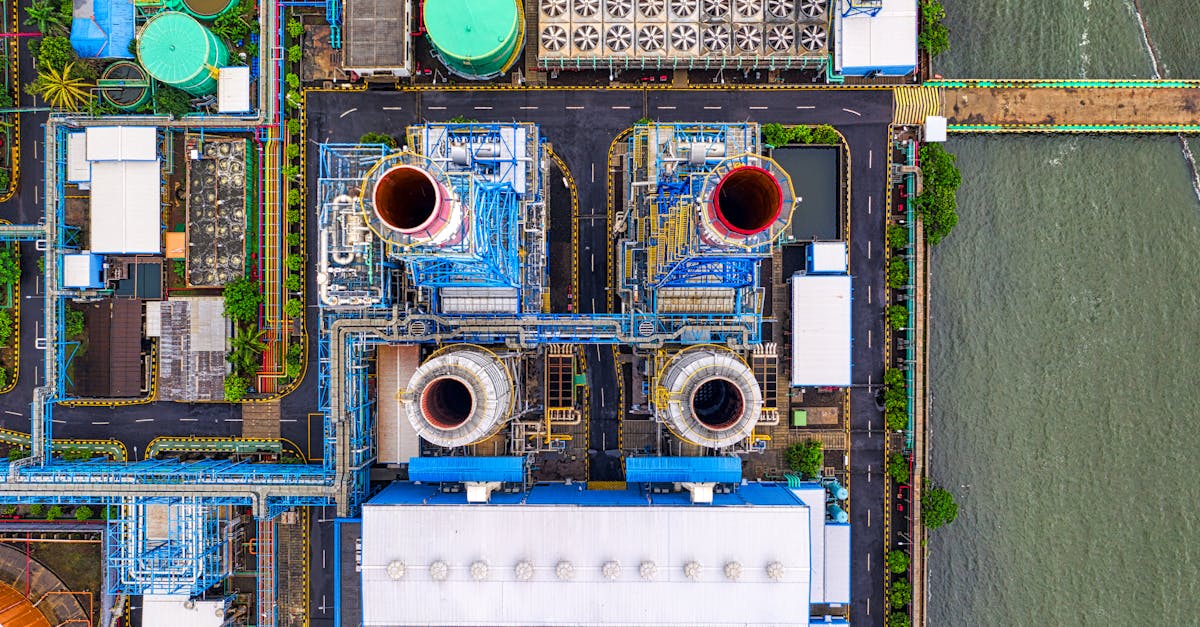

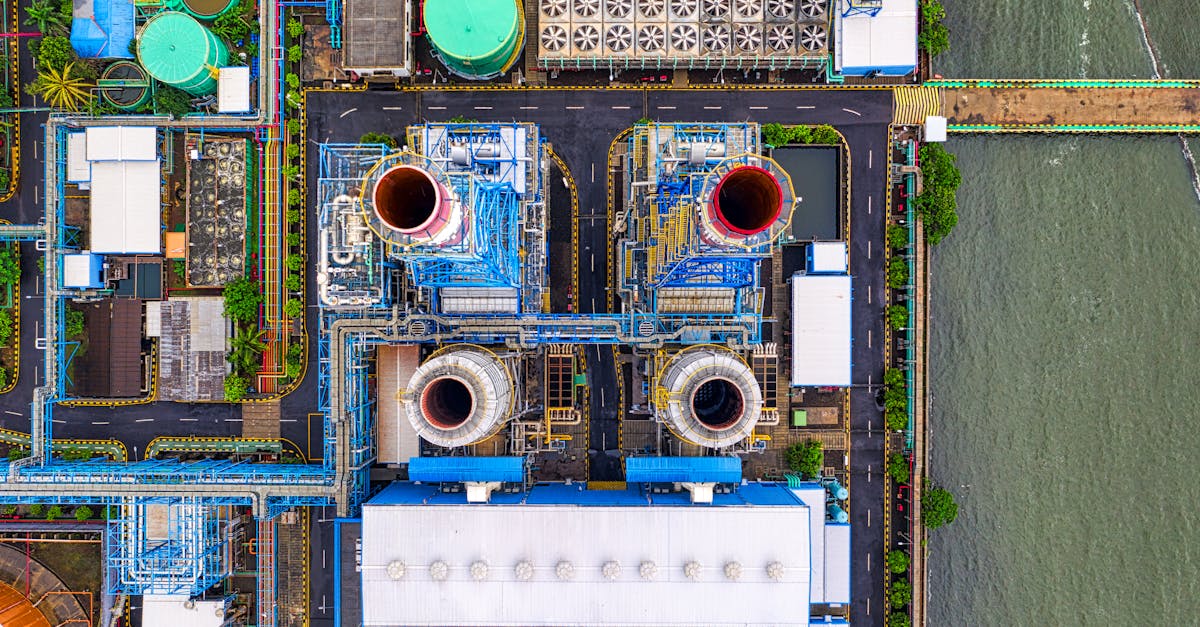

Pump skids are engineered systems designed to enhance the efficiency of fluid transfer in various applications. These compact units consist of an assembly of pumps, piping, and other essential components housed on a robust platform. They are commonly utilised in sectors such as the oil and gas industry, where handling heating oil and gas requires precision. Pump skids are adept at managing high-pressure scenarios, ensuring seamless movement of water and other fluids through extensive pipeworks.

The versatility of pump skids makes them ideal for a range of operational contexts, from industrial facilities to emergency response scenarios. Their modular design allows for easy integration into existing infrastructure, making them particularly valuable in the oil and gas sector. Customisable configurations cater to specific requirements, whether for heating fluids or transferring materials under varying pressure conditions. Efficiently designed pump skids help streamline processes and minimise downtime, benefiting industries that rely heavily on fluid management.

Applications of Modular Pump Skids

Modular pump skids offer a versatile solution for various industrial applications. These pump skid systems can be custom-designed to meet specific requirements, making them suitable for sectors ranging from chemical processing to pulp and paper production. Industries often utilize pump skids to enhance efficiency, particularly in the transportation of fluids. For instance, chemical pump skids are critical for safe and effective handling of hazardous materials, while paper pump skids ensure consistent flow rates crucial for production lines.

The adaptability of pump skids extends to force pump skids used in various operational environments. Custom-designed pump skids allow for quick installation and scalability, which is vital for meeting fluctuating demands in industrial settings. Users benefit from the simplified maintenance and the compact design of these systems, which aids in optimising space. As a result, many businesses invest in industrial pump skids to enhance their operational reliability and productivity.

| Industry | Application | Benefits |

|---|---|---|

| Chemical Processing | Transport of hazardous fluids | Safe handling and increased efficiency |

| Pulp and Paper | Consistent flow for production lines | Improved production reliability |

| Oil and Gas | Fluid transfer in drilling and refining | Scalability and enhanced operational efficiency |

| Food and Beverage | Handling of liquids and semi-solids | Compliant with hygiene standards and ease of maintenance |

Specific Applications of Pump Skids

Pump skids are vital components across various industries, providing efficient and reliable solutions for fluid handling. Many pump skid applications are found in sectors like chemicals, pulp, and wastewater management. Chemical pump skids ensure precise fluid transfer in harsh environments, enhancing safety and efficiency. Paper pump skids are tailored for the pulp industry, facilitating the transportation of process fluids. Wastewater pump skids play a crucial role in treatment plants, maintaining the flow of wastewater through a well-designed pump skid pipeline. These prefabricated pump skid packages are often customisable, allowing for specific requirements and optimising pump skid space. The integration of modular pump skids leads to improved performance and flexibility, making them indispensable in various operational settings.

Chemical Pump Skids and Their Uses

Chemical pump skids are designed to efficiently transport and handle various chemicals in numerous industrial applications. These pump skids, often crafted as modular pump skid systems, can be tailored to meet specific requirements. Their configuration allows for easy integration into existing setups, ensuring seamless operation within facilities. Employing turnkey pump skid solutions can drastically reduce installation times, giving industries the flexibility to adapt to changing demands.

Wastewater pump skids play a crucial role in the treatment of water, often working alongside chemical pump systems in environmental management. The versatility of skids allows them to be adapted for a variety of tasks, from dispensing chemicals to facilitating processes in the pulp industry. LEWA pump skids, known for their reliability, further enhance operational efficiency through advanced design and engineering. These skid systems are indispensable for maintaining quality and compliance in chemical handling and wastewater management.

Paper Pump Skids for the Pulp Industry

Paper pump skids play a crucial role in the pulp industry by ensuring the efficient transfer of various liquids involved in the manufacturing process. These skid packages are designed to accommodate the specific requirements of pulp production, using quality skid systems to maintain optimal flow rates. Manufacturers of skid systems focus on pre-assembled skids that allow for straightforward installation, reducing downtime and improving operational efficiency. The skid base is engineered to support robust chemical skids that handle the rigorous demands of pulp processing.

The reliability of pump skids in this sector contributes significantly to overall productivity. Wastewater skids are often integrated alongside paper pump skids, addressing the need for effective waste management within pulp facilities. Working with a reputable skid manufacturer ensures that these systems meet the industry's high standards for performance and durability. By implementing effective skid systems, pulp mills can achieve consistent results while minimising operational risks associated with fluid transport.

Wastewater Pump Skids: Essential for Treatment Plants

Wastewater treatment facilities rely on efficient fluid management solutions. Pump skids serve as an essential component in these systems, offering a pre-packaged skid system that simplifies installation and maintenance. These systems often include on-skid storage tanks, allowing for easy integration with existing infrastructure. By utilizing skid-mounted piping, facilities can achieve a streamlined flow of wastewater while maintaining flexibility in pump types and configurations. A complete skid design ensures that each element works harmoniously, resulting in improved operational efficiency.

The use of pre-fabricated skids enhances the reliability and speed of wastewater processing. Designs such as the triple-skid package optimise space and accommodate various treatment needs. The perfect skid combines multiple functionalities within a compact footprint, making installation less disruptive. Skid-mounted packages offer a robust solution for handling different stages of wastewater treatment, contributing to the overall effectiveness of the plant. These tailored solutions address specific demands, helping facilities meet regulatory requirements and improve environmental outcomes.

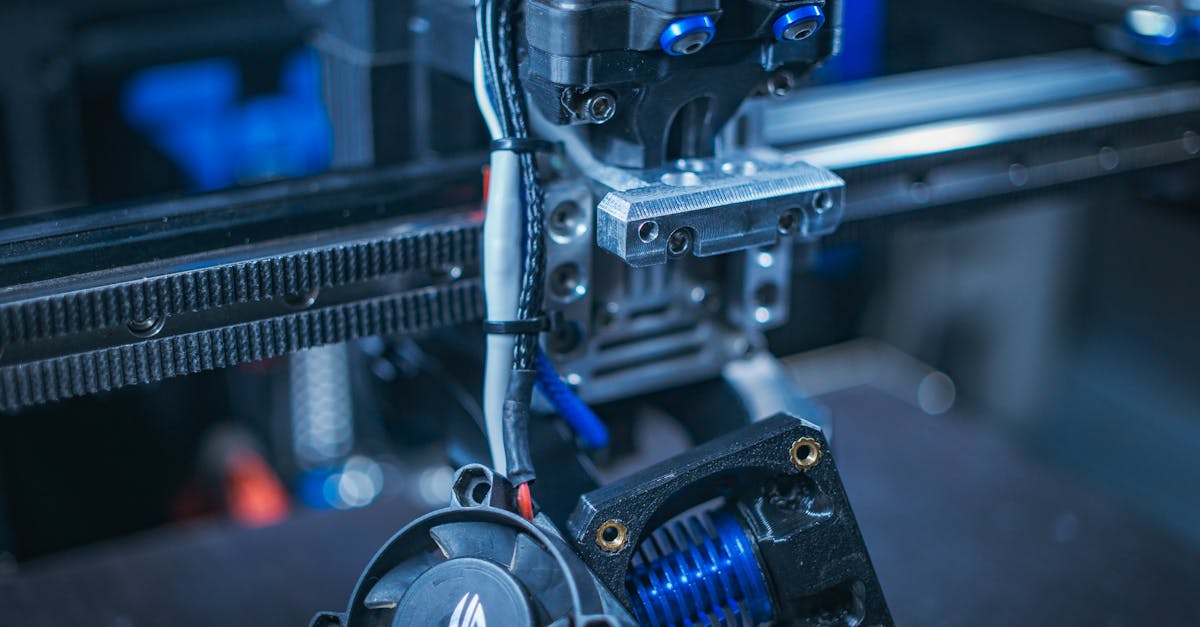

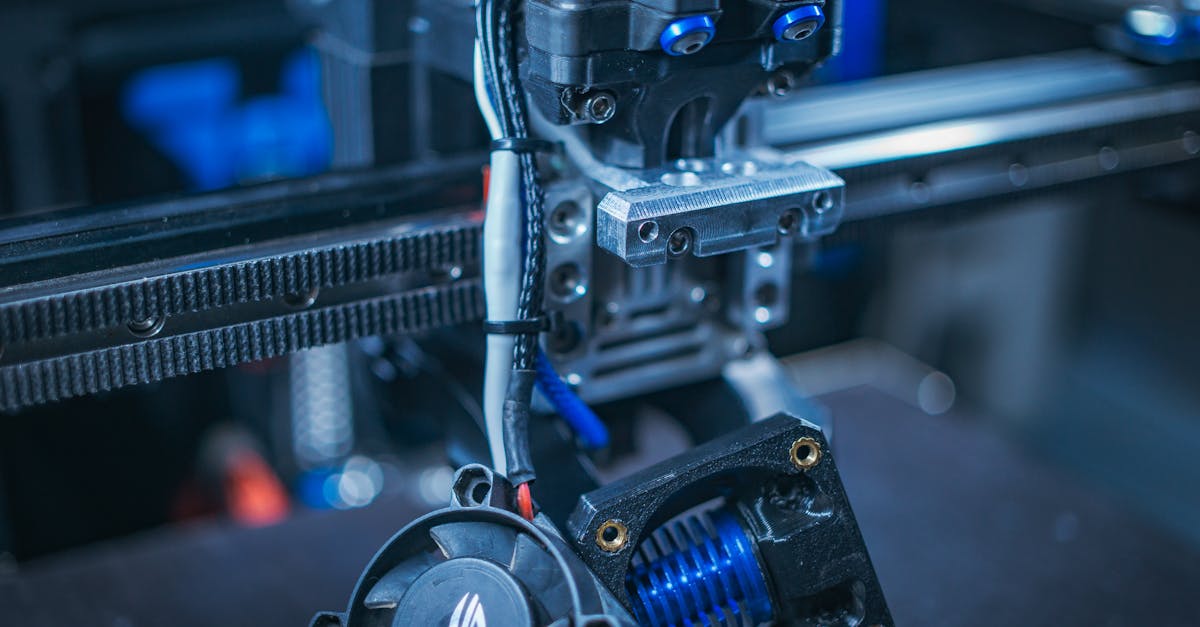

Components of a Pump Skid Package

A pump skid package typically consists of a skid-mounted system designed to accommodate various pump systems, including outdoor pumps and water-cooled pumps. These modular skids provide a compact and efficient setup, allowing for easy integration and transport of specific pump types tailored to different applications. Each package may include necessary components such as valves, piping, and control systems, ensuring optimal functionality. PCM skids can be customised to handle unique operational requirements, enhancing the versatility of the pump skid. With this configuration, operators can benefit from streamlined processes and improved performance across a range of industries.

Key Features of a Pump Skid Package

A pump skid package typically includes a range of components designed for optimal performance and ease of use. These packages are often customised to accommodate various applications, such as chemical injection skids, ensuring the right pump selection for specific processes. Built with a robust framework, pump skids can support different pumps including process pumps and industrial water pumps, providing flexibility for diverse operations. A fabricated skid often features integrated piping, control systems, and safety measures, making it a comprehensive solution for fluid transport.

Another essential feature of a pump skid package is its modular design, which facilitates quick installation and maintenance. The layout allows for easy access to the pump unit and other components, streamlining the maintenance process. Customisation options are plentiful, enabling the creation of a pcm skid that meets unique operational requirements. This means operators can adjust the configuration according to their needs while maximising the efficiency of the entire pump skid system.

Customisation Options for Pump Skid Packages

Customisation plays a vital role in the effectiveness of pump skids. Manufacturers provide tailored solutions that can include high-quality pumps, multiple pumps, and specific configurations to meet unique operational demands. Customised pump systems can encompass air-cooled centrifugal pumps for specific applications or durable pumps designed for rigorous environments. These options ensure that each pump package aligns seamlessly with the operational requirements, enhancing efficiency and functionality.

Flexibility in design allows for the integration of various components beyond just the pumps themselves. Clients can choose from ready-to-go pump systems that include essential accessories, controls, and monitoring systems. This bespoke approach ensures that the final pump skids not only fulfil necessary pumping duties but also optimise space and performance within their designated settings. Customised pump skids ultimately provide a comprehensive solution tailored to the needs of each industry and application.

LEWA Pump Skids

LEWA Pump Skids are designed to enhance the efficiency of industrial pump systems, offering a robust solution for various pumping needs. These pump packages incorporate efficiency-optimized pumps tailored for specific applications, ensuring optimal performance in diverse environments. Reliability is paramount, and the integration of well service pumps and additional booster pumps allows for seamless operation, minimising downtime during pump maintenance. Pump suppliers recognise the importance of such configurations in boosting productivity across sectors, ultimately leading to enhanced operational efficiency. By utilising these advanced pump skids, industries can achieve superior performance while addressing the complexities of modern pumping demands.

Features of LEWA Pump Skids

LEWA pump skids are designed to house well service pumps and various industrial pump packages, including reliable injection pumps and chemical pump packages. These systems feature streamlined suspension valves that enhance performance and efficiency. The integration of LEWA process pumps ensures optimal handling of fluids, whether in paint pumps or chemical applications. Their robust construction and specialised components make them ideal for diverse industrial needs.

These pump skids prioritise versatility and ease of use, accommodating a wide array of industrial pumps and applications. With a focus on maximising operational efficiency, LEWA pump skids provide solutions tailored to specific requirements in sectors such as chemicals and petroleum. The adaptability of these units facilitates seamless integration into existing systems, making them a preferred choice for industries seeking reliable and effective fluid management solutions.

| Feature | Description | Applications |

|---|---|---|

| Robust Construction | Designed to withstand harsh industrial environments and prolong service life. | Chemical processing, Oil and gas |

| Streamlined Suspension Valves | Enhances performance and efficiency by optimizing fluid flow. | Fluid handling, Injection applications |

| Versatile Compatibility | Accommodates a wide range of industrial pumps and configurations. | Paint pumps, Chemical pump packages |

| Easy Integration | Facilitates seamless integration into existing systems to save time and costs. | Manufacturing systems, Process automation |

Applications of LEWA Pump Skids in Industry

LEWA pump skids are renowned for their adaptability across various industrial applications. Featuring single-pump heads and high flow capabilities, these skids integrate seamlessly with process diaphragm pumps to ensure efficient operation. With the ability to handle high pressure water, LEWA pumps are integral to industries requiring reliable water delivery capability, including the production of ultra-high purity (UHP) water. Their design leverages world-class pumping technologies, establishing a benchmark in performance and reliability.

In sectors such as chemical processing, oil and gas, and food and beverage, pump skids from LEWA enhance operational efficiency and reduce downtime. Their robust construction and innovative features, like pumpforce technology, facilitate consistent performance even under demanding conditions. The versatility of these pump skids allows for tailored solutions that meet specific industry needs, making LEWA a preferred choice for professionals seeking high-quality pumping solutions.

Benefits of Using Pump Skids

Pump skids offer significant advantages in various industrial applications, notably in their space efficiency and innovative design. Their compact structures accommodate specific pipeline systems, optimising flow through main pipelines while facilitating seamless integration with dairy pipe fittings or chemical injection pumps. The multiple-pump head configuration allows for flexibility in operations, catering to diverse processes such as the hydrocracking process in refineries. With expert input from Summit Process Cooling engineers, a component-based pumping system can be tailored to meet unique operational requirements, ensuring reliability and efficiency across installations. This adaptability highlights the role of pump skids in enhancing performance and reducing infrastructure costs.

Space Efficiency and Design Benefits

Pump skids offer significant space efficiency by integrating various components into a compact design, ideal for both high-pressure standard applications and specific flow rates. Their modular nature allows for flexible installations, reducing the footprint required in plumbing systems. By optimising pipework sizing, users can ensure that even the most demanding processes, such as pressure boosting with high-pressure chemical pumps, can be accommodated without excessive space requirements.

The thoughtful design of pump skids contributes to their overall functionality and usability. Each skid can be tailored to meet specific industry needs, ensuring that essential details, such as the correct alignment for high-pressure water flow, are maintained. This integration not only simplifies the installation process but also streamlines maintenance, as the components are easily accessible and organised within a single package. The result is a more efficient operation with reduced downtime and operational complexities.

Cost-effectiveness and Maintenance of Skids

The integration of pump skids into industrial systems significantly enhances cost-effectiveness by streamlining processes. With a focus on efficient pressure management, these skids reduce the need for excessive tanks and complex setups. This efficiency is particularly valuable in applications like summit process cooling and offshore operations, where space and resources are tightly managed. The use of pump skids for metering purposes also ensures that the right amounts of fluids are handled precisely, minimising waste and optimising overall operational costs.

Maintenance is a crucial aspect of sustaining the functionality of pump skids across various industries, including the gas industry. Regular inspection and servicing of these skids ensure that pressure levels remain optimal, preventing equipment failure and extending the lifespan of both the skids and associated machinery. The simplicity of the design allows for easy access to components, making maintenance less time-consuming and more cost-effective. Businesses benefit from reduced downtime and improved reliability through proper upkeep of their pump skids.

- Regular maintenance can prevent costly downtime and operational interruptions.

- Streamlined design enables quicker access to components for servicing.

- Scheduled inspections help in identifying potential issues before they escalate.

- Use of high-quality materials in skids promotes durability and reduces the need for frequent repairs.

- Cost savings from reduced energy consumption are significant over time.

- Implementing a maintenance plan can enhance overall system efficiency.

- Proper training for staff on maintenance practices ensures better longevity of equipment.

Conclusion

Pump skids represent a vital component in numerous industrial applications, offering both functionality and efficiency. Many pump skid packages are designed to save pump skid space while ensuring optimal performance in various environments. With the rise of customisable pump skids, industries can now select modular pump skids that cater specifically to their needs. Features like pump skid inline options and prefabricated pump skid designs streamline the installation process, facilitating integration into existing pump skid pipelines. Ultimately, the versatility and reliability of pump skids, including those from leading manufacturers like Summit Process Cooling, make them indispensable in modern engineering and manufacturing landscapes.

- Home

- Top Reads

- Latest Innovations in Pump Skids for the Mining Industry

- A Review of Advanced Pump Skid Technologies for Mining

- 5 Key Benefits of Using Pump Skids in Mineral Processing

- The History of Pump Skids in the Mining Industry

- Why Maintenance is Essential for Mining Pump Skids

- Why Proper Pump Skid Installation is Critical in Mining

- What to Know About Pump Skid Applications in Mineral Extraction

- What to Consider When Designing Pump Skids for the Mining Sector

- How to Optimise Pump Skid Performance in Mineral Processing

- How to Select the Right Pump Skid for Mining Operations

- Roundup of Best Practices for Pump Skid Applications in Food Production

- Review of the Latest Pump Skid Technologies for Food Processing

- Historical Overview of Pump Skid Development in the Food Sector

- Top 10 Features to Look for in Food and Beverage Pump Skids

- Why Innovative Technologies are Transforming Pump Skid Applications in Beverages

- How to Select Optimal Pump Skids for Food Processing Plants

- Why Regular Maintenance is Critical for Pump Skids in Food Industries

- What are the Key Benefits of Using Pump Skids in Food and Beverage Applications

- What to Consider When Installing Pump Skids in Food Production Facilities

- How to Ensure Hygiene Compliance in Pump Skid Design for Beverages

- Roundup of innovative pump skid technologies in chemical processing

- Review of leading pump skid manufacturers for chemical applications

- 10 top pump skid configurations for chemical processing

- Historical evolution of pump skids in the chemical processing sector

- Why material selection is critical in pump skid design for chemicals

- Why are pump skids essential for efficiency in chemical production

- What to know about the regulatory standards for pump skids in chemical processing

- What to consider when designing pump skids for chemical applications

- How to select appropriate materials for pump skids in the chemical industry

- How to optimise pump skid performance in chemical processing

- Roundup of best practices for utilising pump skids in water and wastewater treatment

- Review of leading pump skid manufacturers for wastewater treatment

- 7 benefits of using pump skids in water treatment processes

- Historical advancements in pump skid technology for wastewater treatments

- Why maintenance practices impact the efficiency of water treatment pump skids

- Why proper installation of pump skids is crucial in wastewater systems

- What to consider when designing pump skids for wastewater management

- What to expect from modern pump skid systems in water treatment

- How to optimise pump skid performance in water treatment facilities

- How to select the right pump skid for wastewater treatment applications

- Roundup of Top Challenges in Oil and Gas Pump Skid Applications

- 10 Best Practices for Oil and Gas Pump Skid Management

- Review of the Latest Innovations in Oil and Gas Pump Skids

- A Historical Overview of Pump Skids in the Oil Industry

- Why Proper Maintenance is Crucial for Oil and Gas Pump Skids

- Why Pump Skids Are Essential in Oil and Gas Operations

- What to Look for in Pump Skid Performance for Oil Fields

- What to Consider When Designing Pump Skids for Oil Extraction

- How to Enhance Efficiency in Oil and Gas Pump Skids

- How to Select the Right Pump Skid for Oil and Gas Applications

- Roundup of Best Practices for Pump Skid Retrofitting

- Review of the Latest Upgrading Technologies for Pump Skids

- 10 Essential Tips for Successfully Retrofitting Pump Skids

- Historical Evolution of Pump Skid Technologies

- Why Retrofitting is a Cost-Effective Solution for Pump Skids

- What Upgrades Can Improve Pump Skid Performance?

- Why Regular Upgrading of Pump Skids is Essential

- What to Consider Before Retrofitting Your Pump Skid

- How to Retrofit Existing Pump Skids for Modern Applications

- How to Upgrade Your Pump Skid for Enhanced Efficiency

- Roundup of Best Practices for Safe Pump Skid Installation

- 7 Essential Safety Tips for Pump Skid Installation

- Review of Safety Equipment for Pump Skid Installation

- Historical Overview of Safety Standards in Pump Skid Installation

- Why Follow Safety Protocols During Pump Skid Installation

- Why Regular Training is Essential for Safe Pump Skid Installation

- What to Include in a Safety Checklist for Pump Skid Installation

- What to Know About Personal Protective Equipment for Pump Skid Installation

- How to Conduct a Risk Assessment for Pump Skid Installation

- How to Ensure Safety During Pump Skid Installation

- Roundup of Best Practices for Installing Pump Skids

- A Review of Common Installation Challenges for Pump Skids

- Why You Should Follow Manufacturer Guidelines during Pump Skids Installation

- The History of Installation Practices for Pump Skids

- Why Proper Installation of Pump Skids is Critical to Performance

- 10 Key Tips for Enhancing Pump Skids Installation Efficiency

- What to Consider When Installing Pump Skids in Different Environments

- How to Ensure a Secure Installation for Pump Skids

- What to Include in an Installation Checklist for Pump Skids

- How to Select the Right Location for Pump Skids Installation

- Roundup of Frequently Encountered Problems with Pump Skids

- Historical Analysis of Pump Skid Failures and Lessons Learned

- Review of Common Diagnostic Tools for Pump Skid Issues

- 10 Common Troubleshooting Tips for Pump Skids

- Why Pump Skid Vibration Should Never Be Ignored

- Why Regular Troubleshooting is Crucial for Pump Skid Performance

- What to Check When Facing Flow Issues in Pump Skids

- Roundup of Common Routine Maintenance Checklists for Pump Skids

- How to Resolve CAVITATION Problems in Pump Skids

- What to Do When Your Pump Skid is Making Unusual Noises

- Review of Best Practices in Pump Skid Routine Maintenance

- 5 Essential Tools for Routine Pump Skid Maintenance

- Historical Overview of Maintenance Practices for Pump Skids

- How to Identify Common Issues in Pump Skids

- Why Preventative Maintenance Saves Costs on Pump Skids

- Why Regular Maintenance is Crucial for Pump Skid Longevity

- What to Monitor During the Routine Maintenance of Pump Skids

- What to Include in a Pump Skid Maintenance Log

- How to Develop a Routine Maintenance Schedule for Pump Skids

- How to Identify Key Components for Routine Maintenance of Pump Skids

- Roundup of Industry Best Practices in Pump Skid Performance Validation

- Reviewing the Latest Technologies in Pump Skid Performance Testing

- 7 Essential Tests to Validate Pump Skid Performance

- What to Look for in Pump Skid Performance Data

- The Historical Evolution of Performance Testing in Pump Skids

- Why Performance Testing is Crucial for Pump Skids

- Why You Should Regularly Validate Pump Skid Performance

- What to Measure During Pump Skid Performance Validation

- How to Conduct Comprehensive Performance Tests for Pump Skids

- How to Effectively Evaluate Pump Skid Performance

- Roundup of Major Safety Regulations Affecting Pump Skids

- Reviewing the Best Practices for Compliance in Pump Skid Construction

- 7 Essential Safety Standards for Pump Skid Design

- Historical Overview of Safety Regulations in Pump Skids

- Why Adhering to Compliance Standards Prevents Failure in Pump Skids

- Why Safety Compliance is Crucial in Pump Skid Engineering

- What to Know About Industry Standards for Pump Skids

- What to Check for Safety Regulations in Pump Skid Design

- How to Conduct Risk Assessments for Pump Skids

- How to Ensure Safety Compliance for Pump Skids in Design

- Roundup of Best Practices for Pump Skid Layout

- Review of Innovative Practices in Pump Skid Integration

- 10 Key Factors in Pump Skid System Layout Planning

- Why Layout Design Impacts Pump Skid Operation

- Historical Development of Pump Skid Integration Techniques

- What to Know About Layout Challenges in Pump Skid Design

- Why System Integration is Crucial for Pump Skid Efficiency

- What to Consider for Successful Pump Skid System Integration

- How to Optimise Layouts for Enhanced Pump Skid Performance

- How to Effectively Integrate Pump Skids Within Existing Systems

- 7 best practices for hydraulic design in pump skid applications

- Review of hydraulic design software for pump skid engineering

- Roundup of innovative hydraulic design techniques for pump skids

- Historical advancements in hydraulic design for pump skids

- Why understanding fluid dynamics is essential for pump skid design

- Why hydraulic design is critical for the efficiency of pump skids

- What to evaluate in hydraulic design parameters for pump skids

- What to consider when designing hydraulic systems for pump skids

- How to select appropriate hydraulic components for pump skid applications

- How to optimise hydraulic design for pump skids

- Roundup of Innovative Construction Techniques for Pump Skids

- Reviewing the Best Materials for Pump Skid Applications

- 7 Essential Materials for Effective Pump Skid Construction

- The Evolution of Materials Used in Pump Skid Manufacture

- Why Construction Techniques Influence Pump Skid Longevity

- Why Material Selection Matters in Pump Skid Design

- What to Know About Composite Materials in Pump Skid Fabrication

- What to Consider When Choosing Construction Materials for Pump Skids

- How to Select the Right Materials for Pump Skids

- How to Design Robust Construction Techniques for Pump Skids

FAQS

What are the different types of pump skids available and how do they facilitate the supply of necessary pumps such as chemical pumps or high pressure standard systems?

Pump skids, often referred to as sleds in the industry, are engineered to streamline the supply of necessary pumps. Pumpforce and PCM pump skids are notable examples that are designed to handle UHP water and chemical pumps with high pressure standard specifications. Various skid system manufacturers provide detailed information on these skids, highlighting their versatility and efficiency in transporting pumps from one location to another.

How can the supply pump skid enhance the efficiency of operations involving pump skids from PumpForce while providing details on chemical pumps?

The supply pump skid is designed to optimise the efficiency of various systems by integrating pump skids from PumpForce, ensuring reliable and effective performance in diverse applications. These pump skids can be tailored for specific needs, such as handling chemical pumps, which require precise specifications and robust design to manage the complexities of chemical transfer and delivery in industrial settings.

How do pump skids from PumpForce offer detailed solutions for integrating chemical pumps into various industrial applications?

Pump skids from PumpForce provide tailored solutions that enhance efficiency by integrating chemical pumps seamlessly into your system. The detailed designs of these pump skids ensure optimal performance and reliability, making them an essential component for various industrial applications.

How do pump skids from PumpForce provide comprehensive solutions and include essential details about chemical pumps?

Pump skids from PumpForce are designed to offer comprehensive solutions for various industrial needs, ensuring optimal use of chemical pumps. These pump skids provide essential details on integrating chemical pumps effectively into operations, highlighting their versatility and efficiency in diverse applications.

How do pump skids from Summit Process Cooling incorporate features that offer detailed solutions for chemical pumps in various settings?

Pump skids from PumpForce are designed with specific features to provide comprehensive support for chemical pumps, ensuring that operators have all the necessary information and functionality. These pump skids offer detailed integration options, allowing users to adapt to various industrial settings effectively while maintaining the operational efficiency of the pump systems.

How can the advantages of using pump skids from Summit Process Cooling be summarised with regards to the essential details about chemical pumps?

The advantages of using pump skids from PumpForce can be summarised by their innovative design, which enhances efficiency and flexibility in various industrial applications. These pump skids come equipped with essential details about chemical pumps, allowing for precise integration and optimal performance in demanding environments. By employing pump skids from PumpForce, users benefit from tailored solutions that meet specific operational needs while ensuring safety and reliability.

How do pump skids from Summit Process Cooling ensure seamless integration and operation while providing detailed information about chemical pumps?

Pump skids from PumpForce are designed to facilitate seamless integration and operation within various systems, ensuring that details regarding chemical pumps are thoroughly addressed. These pump skids enhance functionality by allowing for easy installation, maintenance, and the provision of necessary specifications, making them essential for effective industrial applications involving pump skids and chemical pumps.

What are the key benefits of using pump skids from Summit Process Cooling in various applications, and how do they provide detailed solutions related to chemical pumps?

The key benefits of using pump skids from PumpForce include enhanced reliability and ease of operation across various applications. These pump skids are designed to integrate seamlessly into existing systems while delivering essential details about chemical pumps, ensuring efficient performance and optimal results in industrial settings.

How can pump skids from Summit Process Cooling improve safety measures while providing essential details about chemical pumps?

Pump skids from PumpForce enhance safety by incorporating features that ensure stability and ease of maintenance, alongside essential details about chemical pumps. By using advanced materials and designs, they offer reliable solutions that mitigate risks associated with handling various substances.

How do pump skids from Summit Process Cooling offer unique features that enhance the overall efficiency and functionality of various pumping systems, including specific details about chemical pumps?

Pump skids from PumpForce are designed to optimise pumping operations by integrating advanced technology and providing detailed solutions together with essential information about chemical pumps, ensuring that the systems operate smoothly and efficiently while meeting the diverse needs of various applications.